Heavy Structures Laboratory

Areas of research

- High performing structures

- Impact resistant structures

- Strengthening and repair of structures

- Structural health monitoring

- Advanced composites and novel structural materials

- Ultra high performing concrete (UHPC)

- Self-compacting concrete

- Bio-based Building Materials

- 3D printing of concrete

Consultancy work

Qubtest provides a way to arrange consultancy services for testing a wide variety of materials and structures to British and European standards.

Contact: Dr David Hester d.hester@qub.ac.uk

Facilities and equipment

-

Strong floor (12m by 5m)

-

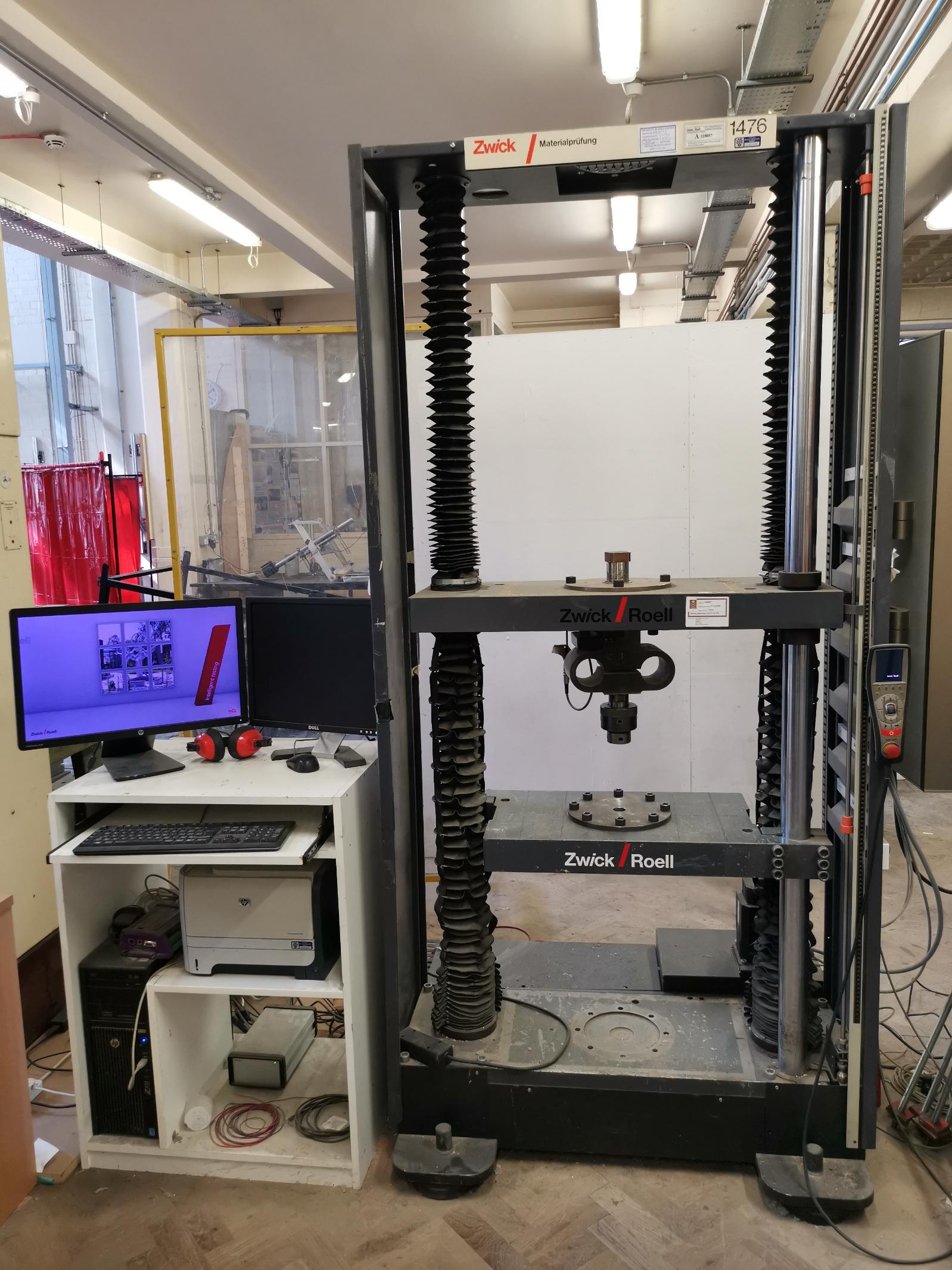

Zwick universal testing machine 100 kN

Test-area height 1m with video extensometer and option to use heated test chamber

-

Large Dartec electro-hydraulic loading frame 600 kN

Test-area 5m x 1.8m

-

3 tonne overhead crane

-

Drop test facility

5m height - 9 to 40 kg mass

-

Environmental chambers for freeze/thaw testing, weathering tests

-

Carbonation chamber

-

Rheology facilities (2 Viscometers, portable vane, Mash cone, Forced bleeding, Plastic shrinkage cone)

-

Concrete workshop and mixing room

-

3000kN cube crushing equipment

-

Curing and conditioning facilities

-

Measurements laboratory

-

Multi-channel, high frequency data acquisition systems

-

Limpet pull-off equipment for in-situ testing of concrete strength

-

Small Dartec electro-hydraulic loading frame 160 kN

-

Avery Denison univ. testing machine 500 kN

hydraulic valve control

-

Berry hydraulic press 4000 kN

pore fluid expression from concrete samples and compression testing of high strength concrete

Lab manager: David Hester

Drop Test Facility Drop Test Impact Zone

Environmental Chamber Large Dartec Hydraulic Loading Frame

Small Dartec Electro-Hydraulic Loading Frame Zwick Testing Zone

Zwick Universal Testing Machine Heavy Structures Laboratory